Vision Inspection in the Food & Beverage Industry

Quality control and inspection is an important part of the food and beverage industry. Forgoing the inspection process will lead to costly errors and possibly the illness or injury of consumers. But is there a more efficient and cost-effective way to execute the vision inspection of foods and beverages?

Vision inspection in the food and beverage industry can have a major impact on the way the industry handles the inspection of products before they get to consumers. This process has benefits that are not seen when the inspection is done by people instead of machines. But what are the benefits of automated inspection as it pertains to the food and beverage industries?

Benefits of Vision Inspection

While there is a more exhaustive list of benefits reaped with a machine vision inspection, the four benefits we talk about in this article are extremely important. These four things, if not inspected properly, can cause problems for the company that has been neglectful or has an insufficient inspection process.

Machine vision inspection equipment is far more accurate than a human being for a number of reasons. When people are inspecting there is the or oversight. People also can’t see through packaging to item a material or item that shouldn’t be there.

Safety

The safety of our food and beverages is something that consumers expect from manufacturers. We do not usually question whether or not what we are eating is safe. However, without machine vision inspection a company will open itself up to the possibility of shipping unsafe products.

Machines can see-through packaging and find out if there is a foreign object in the product that shouldn’t be there and remove it from the production line. They can also detect cross-contamination which would be difficult, if not impossible for a person to find.

Uniformity of Containers

When a food or beverage brand distributes goods to the stores they want all of the packaging to be uniform and undamaged. Machine vision inspection can detect even the slightest packaging anomaly and remove the container from production. The machines can also make sure that each container has the same amount of product inside just by scanning it. Brand integrity is crucial in business. This is something vision inspection can help protect.

Packaging

Packaging has to be sealed properly and not have any spots with questionable integrity. This can damage or contaminate the product on the way to the store, or even in the store. If there is a weak spot in packaging that finally fails then that is a loss for the store and the company.

If packaging issues happen enough, the store will stop carrying that product. Machine vision inspection can help stop packaging problems before they become an issue. By scanning the products the machine can expose packaging weaknesses before the products are shipped to the store.

Labels

Misprinted labels can be potentially deadly to people that have food allergies and intolerances. This can cost a company money in damages if a person is injured because of a label misprint that incorrectly identifies an ingredient or leaves one out. Vision inspection systems will catch these misprints and keep them from being shipped to the stores with the incorrect information.

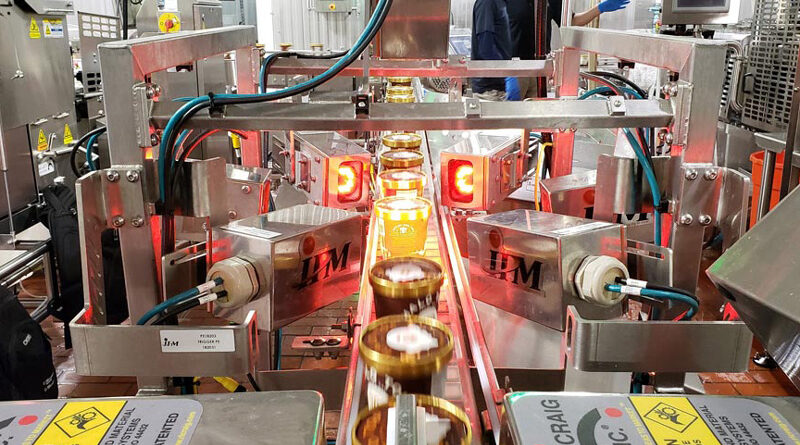

Contact IPM Today

The bottom line, operational improvements need to be addressed in your facility if you want to stay competitive. To learn more about how our inspection products and solutions can benefit your packaging line, contact Integrated Packaging Machinery today at (616) 531-7758 or fill out our form to request a quote.