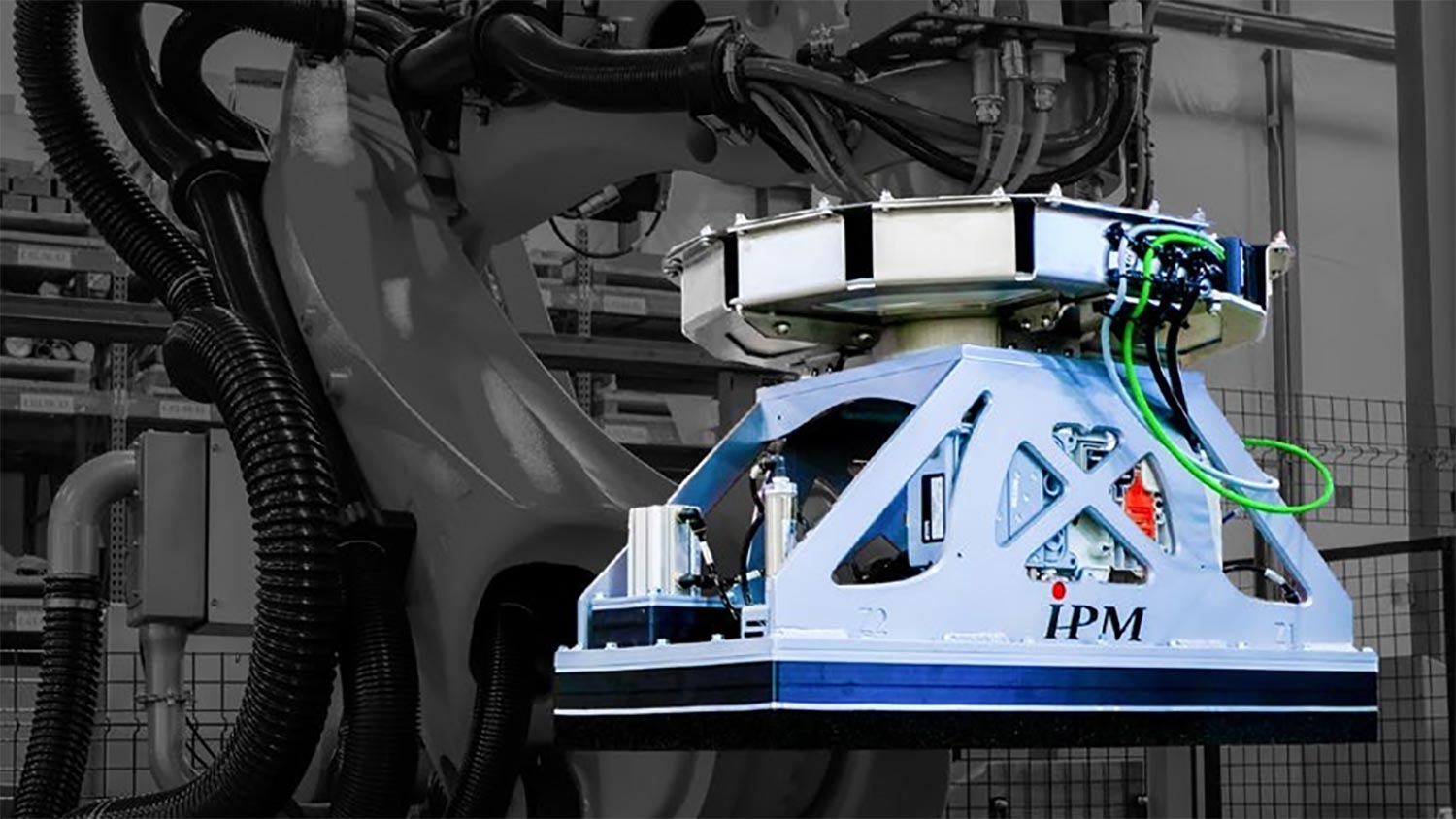

IPM’s AccuTURRET™ Cable Management Technology

- Rockford, Michigan

IPM an integrated packaging solutions leader improves OEE and boosts uptime throughout the entire secondary packaging operation.

The patented IPM AccuTURRET™ cable management technology increases the agility of the End-of-Arm-Tool (EOAT) without increasing the demand on the robot’s wrist.

The AccuTURRET™ improves the accuracy, speed, reach and efficiency of most pick and place robotic arms in a palletizer application. The AccuTURRET™ has the capability to smoothly rotate the EOAT through any sequence within a full 220° of a pallet-building operation. Every cycle function from picking and placing the initial slip sheet to building full or partial case layers to picking and placing subsequent tier sheets is accelerated or streamlined.

The 220° lateral capability of the AccuTURRET™ technology extends a robot’s capability to perform especially difficult pallet building operations in space-limited applications. The AccuTURRET™ can also reduce the complexity and cost of robotic palletizer compressed air systems, improve robot uptime and lengthen maintenance intervals.

The AccuTURRET™ technology achieves this edge in function, performance and cost-to-own metrics by protecting the integrity of the energy, communication and vacuum supply to the EOAT. Robotic palletizer EOAT cabling is a frequent cause of unplanned robot downtime. That’s no surprise given that a high-volume packaging line will ask the robotic palletizer to perform the same 3000 or more complete pick and place cycles per shift. Unless prevented, the hoses and cables controlling the mission-critical functions at the EOAT bend and flex in the same way at the same place in every pick and place cycle. The cabling’s copper conductors and shields are stressed each time. Copper has poor resistance to repeated stressing and very low resistance to shear stress.

Especially in space-limited applications the AccuTURRET™ technology can be expected to improve pick and place accuracy and frequency, mean-time-between-failure, and, system uptime. When paired with a right-sized palletizing robot the AccuTURRET™ solution will not limit specified payload.

In-service stability of a right-sized robotic palletizer in the “Last Mile” position is mission-critical Food and beverage processors can ill-afford to disregard the uptime performance in the “last mile” of their processing and packaging systems. High volume processors annually invest hundreds of thousands, often millions of dollars in monthly utilities, raw material ingredients, and plant, process and corporate brainpower required to deliver the filled and , bottle or can to the downstream packaging system.

Reliable Uptime is critical to high-volume processors of highly-regulated products. Given its “last mile” position in a high-volume packaging line a speed-limited or out of service robotic palletizing operation has the potential to interrupt, delay or even waste all the value created earlier in the process.