Palletizing is the process of stacking large quantities of identical items onto a pallet for shipping. Items are stacked according to weight and in a pattern that promotes stability and product integrity. While the original method of palletizing consisted of people manually loading items onto pallets, nowadays palletizing machines make the process much faster and safer.

Palletizing Products

The palletizing method enables you to stack multiple items in a single bundle, based on volume or weight. In addition to providing better product protection, it can also reduce shipping costs. A few of the steps involved in palletizing include the following:

- Fill Boxes to Maximum Capacity: When packing products in boxes, fill to capacity, while accounting for weight or volume limits. Add an extra layer of protection by wrapping products individually before placing in the boxes. Any corners and gaps between items should be filled to strengthen the boxes and prevent crushing during transport.

- Stack and Distribute Properly: All boxes should be stacked, with weight evenly distributed to avoid any shifting or toppling off of the pallets. Also, stacked items should not overlap the edges of the pallet, otherwise, damage may occur.

- Secure Items with Wrap: Once the pallet is full, the entire unit should be wrapped with multiple layers of plastic wrap to bind the pallet and items together. If necessary, corner protectors constructed of Styrofoam or cardboard can be added to increase overall stability.

- Pallet Types Matter: Another factor to consider when choosing an automated palletizer is knowing the type of pallets you need versus what the system is engineered for. Pallets are made of different materials including plastic and wood and are also available in various shapes, dimensions, and weights. As such, it is a must to maintain consistency with the pallets used.

Palletizing uniquely shaped items is often more challenging than more uniform products. For example, industrial equipment is typically strapped to pallets rather than wrapped. However, in industries that produce massive amounts of products, utilizing automated palletizers can alleviate manual labor and significantly improve productivity.

Types of Automated Palletizers

Automated palletizers were first introduced in the 1970s. These systems consisted of moving items on a conveyor and sorting items that were carefully placed in containers in a standardized pattern. The containers were then placed on the pallet.

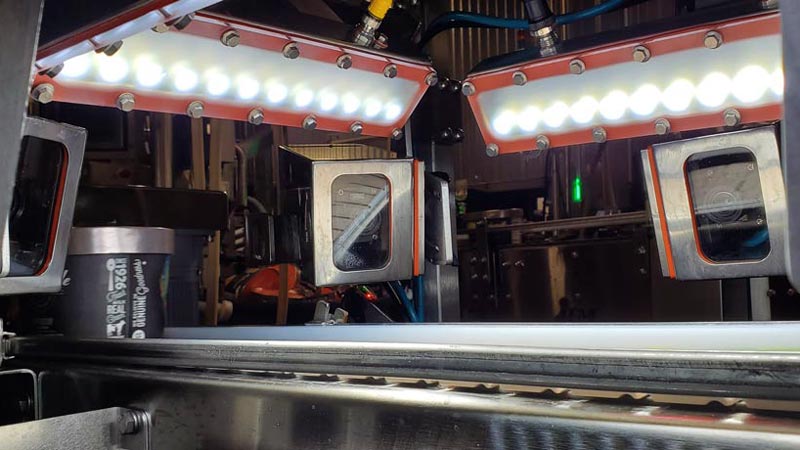

Fortunately, with the technology advancements of today, there are automated systems equipped to palletize similar items and various shaped and sized items alike, using either the robotic or inline palletizer system.

- Inline Palletizer: The inline palletizer is best suited for businesses that focus on a single product style, such as bottled beverages, canned goods, and so on.

- Robotic Arm Palletizer: The robotic system is useful for an industry that creates a wide range of products that are inconsistent in weight, shape, and size.

However, as businesses continue to offer more product diversity, they’re transitioning to a system that includes both the inline and robotic palletizer features. This is referred to as an Omni channel model and provides an effective solution for palletizing customizable loads

Contact IPM Today

Located in the heart of West Michigan, IPM is a leading manufacturer and integrator of downstream packaging line equipment. We serve both US and International clients in the food and beverage industry. If you are interested in learning more about our conveyor systems, contact IPM today at (616) 531-7758 for more information or fill out our online form to request a quote.