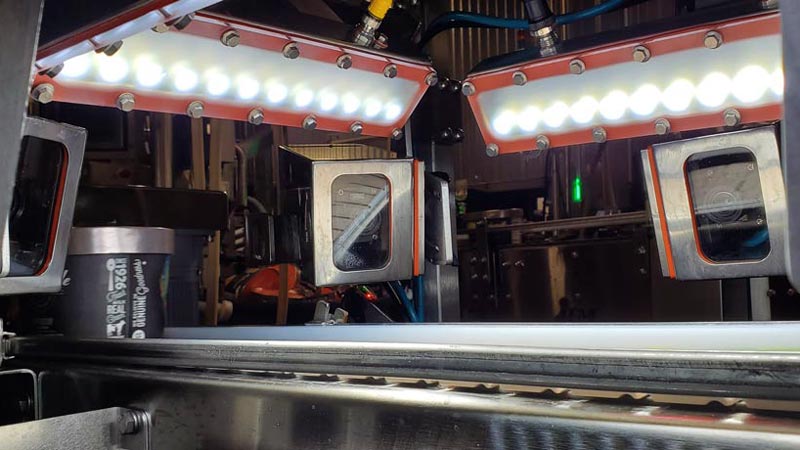

A fully integrated, custom-automated secondary packaging system between filler and palletizer in your ice cream plant will extend your investment and reduce your operating as well as your energy costs. And, critically, it will intentionally protect your product, strengthen your reputation — and reinforce your brand. Plus, you’ll sleep better!

Uptime In Secondary Packaging of Ice Cream Is Mission Critical

You’ve invested in raw materials. Then you blended them, pasteurized them and homogenized them. Then you aged the mix. Then you added liquid flavors and colors. Then you whipped in some air and pumped the mix at the perfect consistency to the filler. Then you filled the cups, cones or containers. You might also add some fruit, some nuts, some candy pieces or other inclusions before the filled and lidded primary package heads into the hardening tunnel.

That’s a lot of investment in capital, in energy, in proprietary recipe thought leadership, in personnel, training and production know-how. Making sure you have the most efficient and highest quality secondary ice cream packaging process in place is critical.

Talk to IPM about all the benefits of leveraging an OEM-neutral, custom-automated approach to intentional uptime in your ice cream secondary packaging system.

“Uptime is the only time that matters” whether or not it\’s #Nationaldairymonth!

Contact Integrated Packaging Machinery

Connect with us today at (616) 531-7758 or contact us here to see what we mean when we say, “Uptime is the only time that matters.”