How Conveyors Are Designed To Ensure Cleanliness

When it comes to food production there are certain conveyor design details that help ensure cleanliness. An important factor, especially in the food industry, because the smallest amount of residue can cause contamination and result in costly repercussions.

Fortunately, through technological advances and , it is possible for food processors to accurately identify the culprit of contamination faster, as well as successfully prevent it. When the right conveyor systems and are in place, not only does it increase efficiency, the risk of hygiene issues are eliminated.

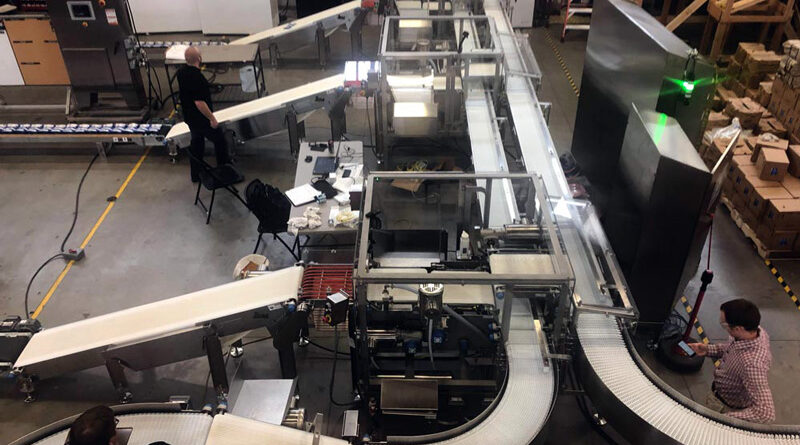

Conveyors have been a game-changer in the food processing industry and most are designed with germ fighting materials and parts that can be quickly disassembled, sanitized, and reassembled with ease. Below, is a list of some key components to consider in a conveyor system, when cleanliness matters.

Why Choose Stainless Steel

Sanitary conveyor systems used in the food industry are primarily constructed with stainless steel materials. Stainless has been used in food preparation and medical facilities for many years because of its strength, resistance to corrosion, and hygienic properties.

Quality food-grade conveyors are generally made of a grade 316 stainless steel material, which is far superior to coated mild steel or other steel alloy products; as these subpar materials are more likely to deteriorate when exposed to harsh cleaning chemicals. Other design details to consider when choosing a safe product include minimal obstructions, such as bolts and rough edges where residue can be easily trapped, and a smooth rotary polish finish because it inhibits microbial growth much better than a factory 2B mill finish.

The Benefits of a Rounded Off Design

While the properties of stainless steel promote safe and effective hygiene, if a conveyor system has areas where food particles or residue can accumulate, no amount of routine cleaning will disinfect.

Thus, look for a system that has rounded frames, seamless belts, minimal fasteners, and few cracks and crevices where product can become lodged.

Consider Power Options

The power-transmission components can affect hygiene aspects as well. Most food plants lubricate the conveyor transmissions with food-grade oils, but this merely reduces the risk of contamination, rather than preventing it.

The motor design is yet another consideration, with options including standalone motors or enclosed gear and drum motors. While standalone motors are most common and therefore cheaper, the enclosed versions are often more energy-efficient and easier to sanitize.

Opt for the Tube Conveyor and Avoid Water Processing

For the most part, food plants avoid the use of disk-based conveyor systems that require water because it hinders productivity and further complicates the cleaning process. Instead, the tube conveyor system offers a cleaning feature referred to as a urethane pig, which removes residue and preserves particles that can be reused later. This feature increases efficiency and safety, and reduces in-depth cleaning requirements to a weekly task.

Bottom line, due to the complexity and size of conveyor systems, keeping them sanitized is not a simple task. But when designed with the features suggested above, cleaning and maintenance can be achieved more efficiently.

Contact IPM Today

Located in the heart of West Michigan, Integrated Packaging Machinery is a leading manufacturer and integrator of downstream packaging line equipment. We serve both US and International clients in the food and beverage industry. If you are interested in learning more about our conveyor systems, contact IPM today at (616) 531-7758 for more information or fill out our online form to request a quote.