Is your manufacturing process still producing too many errors? One solution your business should consider is integrating inspection systems. These systems help businesses streamline production, improve product quality, and eliminate unwanted costs associated with product errors and mistakes.

Continue reading below to learn more about inspection systems or contact Integrated Packaging Machinery today to talk to our system specialists.

What is an inspection system?

An inspection system is an automated and cost-effective way to inspect a variety of products in real-time. This step can be essential for ensuring that the manufacturing line is producing the highest quality product as well as that the physical characteristics and specifications of each item is being met before it leaves the warehouse.

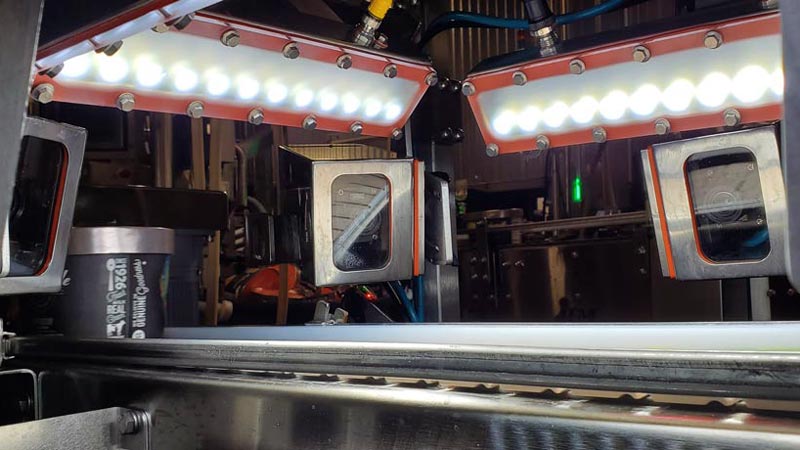

These solutions can be embedded into your manufacturing line to provide a constant stream of information while also measuring and sorting parts at high speeds. Vision inspections on conveyor lines are most common in the manufacturing industry. However, they can also be found in a variety of different industries where quality control is necessary. Our services will help to integrate a vision inspection system into your material handling line.

How do machine systems work?

Inspection systems can recognize unique product shapes, measure parts quickly and efficiently, and verify that parts are in the correct position. These systems come equipped with a wide range of specialty features such as a camera or multiple cameras, barcode scanners, x-ray machines, foreign object detectors, and even video inspection tools.

Computer software that is built into the inspection system will instantly analyze images or data that are captured as products pass through the process and trigger some sort of an action based on that analysis. These elements are necessary for recognizing errors or defects quicker and more efficiently.

In addition to real-time results, the information captured by the vision system can help identify problems with the manufacturing line or a specific function of the process, they can help stop inefficient or ineffective processes, as well as identify unacceptable products before they get shipped to the consumer.

Why should I implement an inspection system?

Inspection systems allow companies to conduct 100% inspection of parts for quality control purposes. By combining various technological features, you can design and build an inspection system that can be easily implemented into your conveyor system. These systems will help you fix issues and improve overall quality of your products by using the data collected during the inspection process.

Advantages Of Inspection Systems

These inspection systems provide automated quality control, which will allow you to enjoy a reliable system that delivers time and time again. As a result, you can ensure that every product your business produces will meet the customers’ specifications.

Bottom line, inspection systems lead to higher quality, increased productivity and lower production costs for your conveyor line . If you are interested in learning more about our packaging products and solutions, contact us today at (616) 531-7758 for more information or fill out our online form to request a quote.