Traditional packaging is passive. It protects food but doesn’t interact with it.

Active packaging, by contrast, is designed to interact with the contents or internal environment of the package to extend shelf life, improve safety, and maintain product quality.

This can include materials that:

- Absorb oxygen or moisture

- Release antimicrobials or preservatives

- Regulate internal temperature or humidity

- Absorb ethylene gas

- Neutralize odors or harmful gases

- Indicate freshness or spoilage

The result is packaging that works harder—for both manufacturers and consumers.

Key Technologies Driving Active Packaging

Oxygen Scavengers

Oxygen can speed up spoilage and discoloration. Oxygen scavengers reduce oxygen levels inside sealed packages, helping preserve the product\’s taste, texture, and appearance. Common applications include snack foods, meats, and beverages.

Moisture Regulators

Moisture-sensitive foods benefit from desiccants or humidity-controlling films that reduce sogginess or drying out. These are often found in baked goods, produce, and meal kits.

Antimicrobial Agents

Some antimicrobial packaging is embedded with or coated in antimicrobial agents that inhibit the growth of bacteria, mold, or yeast—especially valuable in dairy, produce, and seafood applications.

Ethylene Absorbers

Ethylene gas accelerates ripening. Packaging materials that absorb or break down ethylene help slow spoilage in fruits and vegetables, especially in transit.

CO₂ Emitters

By maintaining modified atmosphere conditions inside a sealed container, CO₂ emitters extend the shelf life of items like cheese, poultry, and ready-to-eat meals.

Smart vs. Active Packaging: What’s the Difference?

It’s easy to confuse smart packaging with active packaging, but they serve different functions:

- Active packaging directly affects the food or internal package environment.

- Smart packaging provides information about the food’s condition (e.g., temperature changes, spoilage indicators, or tampering).

Today, many manufacturers are combining both to create a complete package solution that’s protective, intelligent, and trustworthy.

Why It Matters: The Benefits of Active Packaging

✅ Longer Shelf Life

Active components reduce exposure to elements that cause spoilage—keeping food fresh longer across the supply chain and in consumer homes.

✅ Enhanced Food Safety

Antimicrobial food packaging and oxygen control reduce contamination risks and keep food safer to consume.

✅ Lower Food Waste

Longer-lasting products mean fewer spoilage-related losses at retail and in households—supporting sustainability initiatives.

✅ Increased Consumer Trust

Reliable freshness and safer food builds loyalty and confidence in your brand.

“Active packaging is more than an innovation—it’s a game-changer. From shelf life extension to food safety and waste reduction, it’s helping reshape how food is packaged, sold, and consumed.”

Active Packaging in Action: Real-World Applications

Active packaging is already in use across several food sectors:

- Meat & Poultry: Modified atmosphere packaging combined with antimicrobial films to preserve color and flavor.

- Produce: Bags with ethylene scavengers extend freshness of ripening fruits and leafy greens.

- Seafood: Odor absorbers and oxygen scavengers help maintain freshness in transit.

- Baked Goods: Moisture-absorbing films prevent mold and sogginess.

- Dairy: Specialized films extend shelf life while maintaining texture and taste.

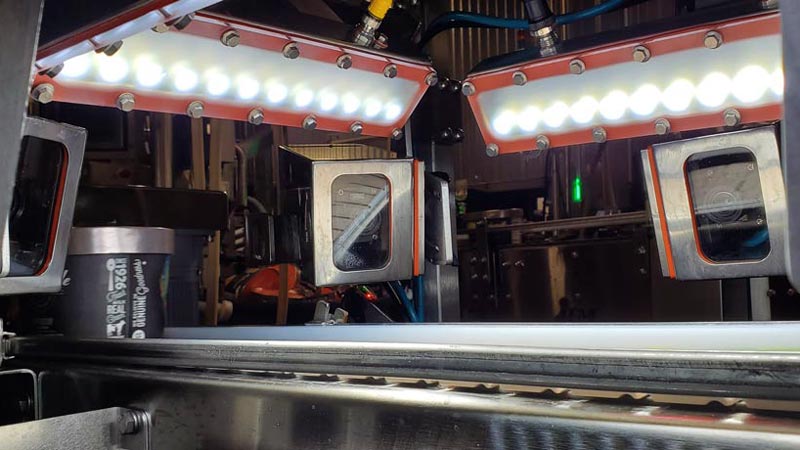

At IPM, we help manufacturers adapt their automation systems to handle these advanced active and intelligent packaging materials and formats—ensuring efficiency at every step of the line.

Implications for Packaging Line Integration

Successfully implementing active packaging requires more than switching materials—it may also mean retooling your line.

Packaging systems must now:

- Handle flexible or multilayer films

- Integrate sachet or pad placement

- Maintain modified atmosphere sealing

- Enable seamless transition between formats

At IPM, we specialize in engineering turnkey systems that accommodate these evolving technologies without compromising throughput or uptime.

What’s Next for Active Packaging?

The future of active packaging is exciting—and sustainable.

Expect to see:

- Biodegradable active materials replacing traditional plastics within antimicrobial food packaging

- Recyclable and compostable options with embedded active properties

- Sensor-enhanced packages that integrate freshness indicators with supply chain tracking

- More demand for clean-label, preservative-free food that stays fresh thanks to smart packaging

As consumer priorities evolve, packaging technologies will continue to converge with automation and AI for even smarter, more sustainable solutions.

Active Packaging & IPM

Active packaging is more than an innovation—it’s a game-changer. From shelf life extension to food safety and waste reduction, it’s helping reshape how food is packaged, sold, and consumed.

At IPM, we’re committed to engineering systems that work in harmony with the next generation of packaging solutions. Whether you’re exploring active films, antimicrobial sealing, or ethylene control systems, we help you bring it all together with smart, reliable automation—from input to output.

Let’s talk about how to upgrade your packaging line to take advantage of active packaging.

Contact us at (616) 531-7758 or message us here to find out what we mean when we say, “Uptime is the only time that matters!”