The journey from dairy farm to grocery store shelf is a fast-paced, highly regulated, and increasingly complex process. For decades, dairy producers have faced the challenge of moving perishable products quickly and safely through the packaging and distribution pipeline. Now, with the rise of advanced automation technologies, including cobots (collaborative robots), smart conveyors, and integrated control systems, the dairy packaging solutions are undergoing a transformation. These innovations in automated dairy packaging systems are not only keeping pace with market demands but setting new standards for efficiency, safety, and sustainability.

Fast, Cold, and Compliant: The Unique Demands of Dairy Packaging

Dairy is unlike any other segment in food production. It must be processed, packaged, and shipped quickly to maintain freshness and safety. Temperature control is critical. So is speed. But equally important is the ability to meet strict industry regulations, including FDA and USDA standards, as well as evolving retail requirements for traceability and food safety.

This trifecta of demands—fast, cold, and compliant—places tremendous pressure on packaging lines. Traditional manual processes or outdated machinery often create bottlenecks, product losses, or compliance risks. Automation, by contrast, is purpose-built to meet these challenges.

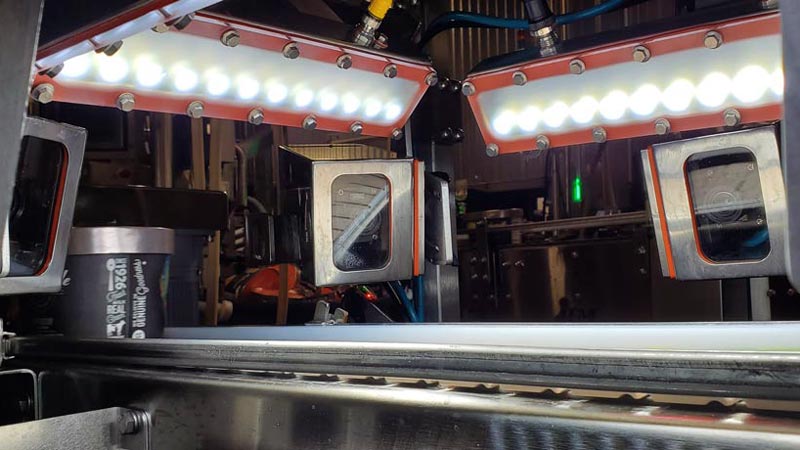

Automated dairy packaging systems help ensure products move seamlessly from fill lines to final packaging without breaking the cold chain. Smart sensors and machine vision systems monitor product integrity, detect labeling issues, and validate packaging seals in real-time. With traceability and compliance requirements nly growing more stringent, these systems are also integrated with MES and ERP software to provide full digital records of every step in the packaging process.

Whether it\’s milk in PET bottles, cheese blocks in vacuum packs, or yogurt in multi-packs, modern dairy packaging lines need to be precise, hygienic, and adaptable. Dairy packaging companies today must utilize automation that delivers on all three fronts.

Cobots + Conveyors in Motion: Increasing Output and Consistency

Collaborative robots (cobots) are a game changer in the dairy space. Unlike traditional robots that require caged environments, cobots can safely work alongside human operators within dairy packaging companies, making them ideal for handling repetitive or ergonomic-heavy tasks like case packing, palletizing, and quality inspection.

Cobots shine in dairy packaging solutions because they are flexible, programmable, and quick to deploy. Need to switch from 2% milk cartons to almond milk bottles? No problem. Cobots can be reprogrammed for different SKUs with minimal downtime. This versatility is critical in an industry where SKUs and packaging formats are continually evolving to meet consumer preferences.

Conveyor systems within automated dairy packaging systems have also evolved to support greater flexibility and control. Servo-driven conveyors and smart belt systems can now adjust speeds dynamically, buffer product during upstream or downstream delays, and integrate seamlessly with robotic pick-and-place systems. For dairy facilities that must maximize throughput without compromising product integrity, this combination of cobots and conveyors offers unmatched efficiency.

When synchronized correctly, cobots and conveyors create a continuous flow of motion that keeps packaging lines moving—even when demand surges. That translates to higher output, more consistency, and better use of floor space.

“As demand for dairy products grows, packaging operations must evolve. Automation is no longer a luxury; it’s a competitive necessity.”

Reducing Waste, Downtime, and Labor Pressure in Dairy Lines

The margin for error in dairy packaging is razor thin. A misaligned label, a damaged container, or a leak in a heat seal can mean thousands of dollars in product loss—not to mention potential regulatory headaches or recalls. Automation helps prevent these issues before they happen.

Machine vision systems and automated inspection stations catch problems in real time, allowing corrective action before defective products leave the line. This leads to a measurable reduction in waste and rework.

Automation also improves line uptime. Predictive maintenance sensors monitor equipment performance and trigger alerts before breakdowns occur. Modular machine designs and plug-and-play components allow for fast repair and replacement, minimizing production interruptions.

Perhaps one of the biggest benefits automation brings to dairy processors is relief from labor shortages. Recruiting and retaining skilled workers is increasingly difficult, especially in environments that are cold, wet, and repetitive. Automation doesn\’t replace people—it empowers them. By shifting workers away from manual handling tasks and into roles that require oversight, programming, or quality assurance, companies can elevate job satisfaction while maintaining productivity.

Moreover, cobots can work continuously, don’t require breaks, and deliver consistent performance across every shift. For high-volume dairy plants that run 24/7, this consistency is crucial.

Beyond Packaging: A Smarter Dairy Supply Chain

The benefits of automation extend well beyond the packaging line. As dairy producers integrate automated dairy packaging systems across their operations, they gain access to real-time data that can inform purchasing, production planning, logistics, and inventory control.

With IoT-enabled packaging machinery, dairy processors can monitor KPIs such as OEE (Overall Equipment Effectiveness), yield, and waste in real time. This visibility enables better decision-making and continuous improvement across the plant.

It also opens the door to predictive analytics. By analyzing trends in machine data and environmental conditions, companies can fine-tune line speeds, prevent bottlenecks, and forecast maintenance needs before they become costly disruptions.

The Future of Dairy Packaging Is Integrated

As demand for dairy products grows—alongside consumer expectations for quality, sustainability, and variety—dairy packaging solutions and operations must evolve. Automation is no longer a luxury; it\’s a competitive necessity.

At Integrated Packaging Machinery (IPM), we specialize in designing and integrating turnkey automation solutions that help dairy producers meet these challenges head-on. From cobots to conveyors, sensors to software, we bring every component together into a cohesive, high-performing packaging line.

From moo to market, automation is making dairy packaging faster, smarter, and more sustainable. And the best part? We’re just getting started.

Contact us here or call the IPM team at (616) 531-7758.