Food manufacturers face many challenges, but the two biggest operational improvements they should consider continue to center around are the concepts of robotics and automation.

One report, known as the 2019 Trends and Advances in Food Packaging and Processing, looked into operational improvement data from the last two years and how it has developed, noting that implementations of automation are in the top spot when it comes to the improvements food manufacturers are making. This is to be expected as food manufacturers continue to see automation as the most viable and cost-effective modern solution to fill the gaps of worker availability that impact food manufacturing at every scale.

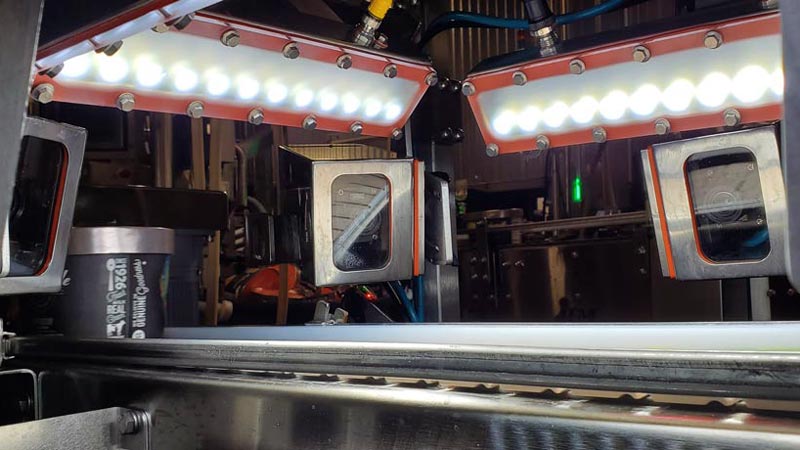

Implementing Robotics Improvements

Meanwhile, the same report found that robotics implementation has risen to the second position on the list of operational improvements. In fact, 2 out of every 5 food companies are deploying some utilization of robotics, whereas just 1 in 5 of the same were doing so a couple years back. This pattern of positive growth is expected to continue as robotics become more accessible, even to smaller manufacturers, and even more advanced and efficient with the likes of machine learning and intelligent maintenance.

However, one Packaging System Development Engineer addressed the fact that there\’s no one-size-fits-all solution, stating: “Installing more robotics depends on each business model, the line, the product, and the plant; we need greater involvement from our suppliers with robotics integration.\” When it comes to deciding whether robotics and automation are good additions for your company, cost will obviously be the biggest consideration and greatest hurdle to overcome.

What Food Manufacturers Are Saying

When it comes to survey results amongst food manufacturers, an unsurprising 36% of respondents directly cited cost justification as their biggest obstacle in making operational improvements. Another 22% of respondents cited a lack of technical skills as a major challenge and another 14% acknowledged the dire need for advanced team training to handle the implementation of new technology effectively.

As far as expert recommendations go, when considering robotic installation and integration services, they suggest building a value proposition that analyzes a comprehensive look at the potential return on investment of such services. As one example, training with the use of augmented reality could be viable with the use of intuitive and enhanced reality tools and training to help guide machine operators across every position within a manufacturing plant. Taking a wider look at the list of top five operational improvements for the industry, OEE (Overall Equipment Efficiency) also made the list, reaching a new high of 32% from just 18% a few years back.

Bottom line, operational improvements need to be addressed in your facility if you want to stay competitive. To learn more how our packaging products and solutions can benefit your packaging line, contact Integrated Packaging Machinery today at (616) 531-7758 or fill out our form to request a quote.