Specifying the optimal dairy packaging machinery is a crucial decision for any ESL, Shelf Stable, Cheese, Ice Cream, Cultured Product or Fluid Milk processing facility. The best-fit combination of dairy packaging machines can protect the brand, preserve product quality, reduce waste, reduce production costs, improve overall efficiency, and substantially improve predictable uptime. This article will guide you through the key factors to consider when selecting machinery for your dairy packaging needs.

Define Your Packaging Requirements

Before diving into the packaging system specification process, it\’s essential to clearly define your packaging requirements. Consider factors such as the types of dairy products you produce (e.g., milk, cheese, yogurt), the packaging materials you plan to use (e.g., bottles, cartons, pouches), packaging sizes, and desired production capacity. Having a clear understanding of your needs will help you narrow down your options.

Evaluate Product Compatibility

Different dairy products have varying characteristics that affect the specification of packaging technology and series of technologies. Consider factors such as viscosity, texture, and temperature sensitivity when evaluating technology options. Ensure that the technology specified will handle the specific requirements of your dairy products without compromising quality.

Consider Packaging Materials

The choice of packaging materials is closely linked to the type of technology required for optimal uptime performance. For example, if you use plastic bottles, you\’ll require filling and capping equipment that is compatible with plastic containers. If you opt for cartons or pouches, you\’ll need different combinations of technology. Ensure that the technology you specify, or specified on your behalf is compatible with the packaging materials your brand requires and can provide the necessary sealing and closure features.

Production Capacity

The production capacity of your dairy processing facility is a critical factor in specifying the dairy packaging systems installation, packaging technology, machine center sequence as well as conveying, buffering and accumulation strategies between machine centers. Calculate your current production volume and estimate future growth. Specify technologies that not only meet your current needs but provide capacity to address your growth aspirations. Consider factors such as the rate, the orientation, the automation, and output capacity of the machinery to ensure it aligns with your production goals.

Automation and Efficiency

Efficiency is a key consideration when choosing your machinery. The right automation and control strategy will significantly improve uptime, productivity and, importantly reduce labor costs. The right control strategy will also contribute to your sustainability aspirations. Evaluate the level of automation offered by different technology and control options. Fully automated packaging systems will optimize the filling, sealing, labeling, and palletizing sequences while reducing the need for manual intervention.

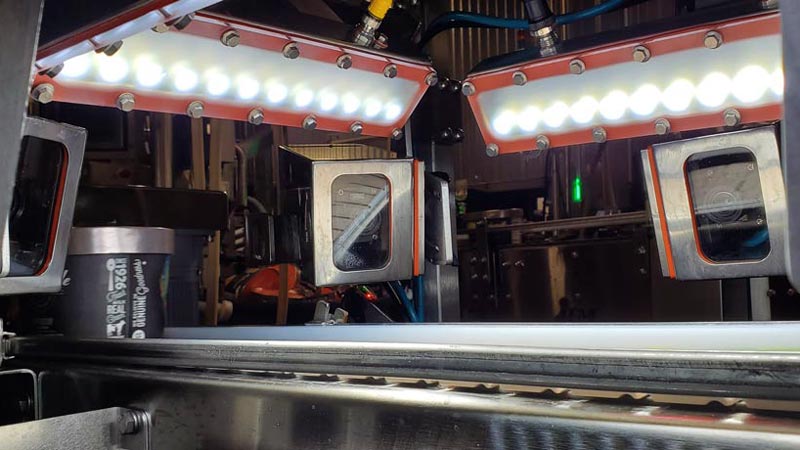

Sanitary Design

Dairy products processing and packaging almost always requires a high level of hygiene and sanitation to meet regulatory standards and ensure product safety. The technology installed in those highly regulated environments must be designed with easy cleaning and maintenance in mind. Stainless steel construction is often preferred in the dairy packaging industry because it is corrosion-resistant and can withstand frequent cleaning and sanitizing procedures. Ensure that the installed technology not only meets your production aims — but that it also meets the expectations of your customers and is compliant with regulations. The installation team must be fully aware and compliant with the hygienic standards in your plant.

Compatibility with Existing Equipment Within Your Dairy Packaging Systems Installation

You no doubt already have dairy processing and packaging technology in place. It’s imperative that you consider how the new packaging machinery will integrate with your balance of plant. Compatibility between components of your production line is essential for optimizing uptime. Evaluate whether the new specification can be seamlessly integrated with your current equipment.

Training and Support

Proper training and support are crucial for the successful operation of dairy packaging technology and systems. Choose a dairy packaging systems supplier or manufacturer that offers comprehensive training for your operators and maintenance staff. Additionally, be sure to inquire about the availability of technical support and spare parts. On the one hand it should be expected that parts and spares are part of the specification – but on the other hand, the reality of long lead times don’t always align with that expectation. A reliable team of OEM-supplier and Systems Integrator collaborators can be instrumental to keeping your production running smoothly.

It’s essential that each machine center is synched with the one it follows as well as the one it precedes. All the OEM machine centers must be specified, installed, integrated and controlled to work together.

Regulatory Compliance

Compliance with food safety and packaging regulations is non-negotiable in the dairy industry. Ensure that the technology you specify adheres to all relevant industry standards and regulations, such as FDA, USDA, or local health authorities. This includes considerations like proper labeling, traceability, and compliance with hygiene and safety standards.

Budget and Total Cost of Ownership

While it\’s essential to consider your budget, it\’s equally important to think about the total cost of ownership (TCO) of your dairy packaging machines. TCO includes not only the initial purchase price but also maintenance, energy consumption, spare parts, and labor costs. Assess the long-term financial implications of your technology specification to make an informed decision.

Warranty and Maintenance Agreements

Evaluate the warranty and maintenance agreements offered by the machinery supplier. A robust warranty on your dairy packaging machinery can provide peace of mind and protect your investment. Additionally, inquire about the availability of preventive maintenance services and how quickly the supplier can respond to any technical issues that may arise.

Reputation and References

Research the reputation of systems integrators, technology suppliers and installation experts in the dairy industry. Read reviews, seek recommendations from industry peers, and ask for references from the suppliers themselves. A company with a strong track record of delivering reliable machinery and excellent customer service is more likely to meet your needs.

Future-Proofing

Consider the longevity of the dairy packagingmachines you\’re considering. Technology in the dairy industry is continually evolving, so it\’s essential to specify technology that is designed to adapt, at least in part, to future advancements. Specifying modular or upgradable systems can help you stay competitive and flexible in a changing market.

Environmental Impact

Sustainability is a growing concern in the dairy industry. Evaluate the environmental impact of the packaging system you specify. Look for features such as energy-efficient operation, reduced waste generation, and compatibility with recyclable packaging materials. Demonstrating a commitment to sustainability can also be a valuable brand differentiator for your product mix.

Test Runs and Trials

Whenever possible, conduct factory acceptance tests (FAT’s) with potential dairy packaging systems suppliers, OEM’s and integrators before making a final specification decision. This allows you to assess the packaging system’s performance under simulated operating conditions and identify any potential issues or bottlenecks. A site acceptance test (SAT) in your facility, following integration, installation and commissioning It\’s an important component of in validating that what worked in a controlled environment will work in your real-world processing and packaging plant.

Dairy Packaging Integration Solutions from IPM

Specifying the optimal dairy packaging technology solutions and systems requires careful consideration of your plant and utilities and, product characteristics, production capacity, future aspirations, staffing and budget. By thoroughly evaluating these factors and conducting thorough research, you can make an informed decision that enhances the efficiency and competitiveness of your dairy processing facility.

Remember that every machine center is actually a component in a larger system. It’s essential that each machine center is synched with the one it follows as well as the one it precedes. All the OEM machine centers must be specified, installed, integrated and controlled to work together. Machine center technologies, regardless of their stand-alone performance promises must deliver a properly integrated function. Product quality, brand growth, customer satisfaction, staff safety, plant metrics and business model success hang in the balance and must be aligned with your dairy packaging systems installation.

Contact us at (616) 531-7758 or message us here to find out what we mean when we say, “Uptime is the only time that matters!”