Operator competency. It is the strategic advantage most manufacturers overlook. Without it, even the most advanced automation and packaging system integration cannot achieve the results it is engineered to deliver. Uptime depends on equipment, but it is driven by operators with the skill and confidence to run the system with precision.

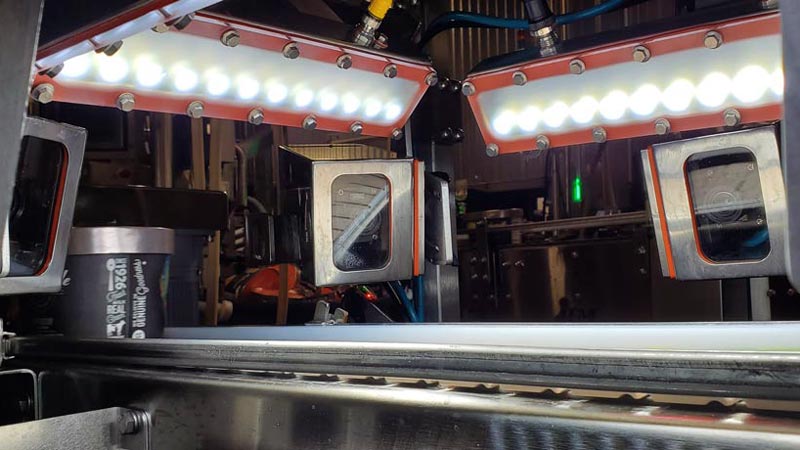

IPM engineers packaging lines to perform as integrated systems. EQUIPS™, short for Education Quantified Utilizing Identified Performance Standards, is our packaging line training program that extends that system-level thinking to the teams responsible for daily operation. Through OEM neutral training on your exact equipment and subsystems, operators learn to manage the full line with precision. EQUIPS prepares teams to execute confidently from the first run forward.

Competency That Drives Uptime

Plants are under constant pressure to increase throughput, maintain compliance, and adjust to shifting production demands. In this environment, training is not a requirement. It is a performance strategy. EQUIPS strengthens operator competency packaging-wide, turning training into a measurable contributor to uptime.

Operators and maintenance teams who understand how equipment, subsystems, and controls function as an integrated machine center make better decisions at speed. They complete changeovers with accuracy. They identify emerging issues before impact downtime through packaging maintenance training that strengthens their ability to act early. The result is a more predictable, stable line.

EQUIPS gives teams the structure to build and sustain that capability. On-site facilitation, hands-on instruction at the line, and digital training modules equip operators, technicians, and supervisors with the practical skills needed to perform with confidence on day one and continue developing long after startup.

Training Impacts Output

A packaging line without EQUIPS training experienced a 30% drop in output after installation.

Source: IPM internal data

A Structured Approach to Building Competency

EQUIPS uses a structured, multi-format model to build the system-level competency operators need to run the line with precision.

The EQUIPS curriculum is continuously updated, ensuring training aligns with evolving equipment, controls, and line performance standards.

Protecting Uptime Through Competency

Uptime is protected in the decisions operators make long before a stop occurs. EQUIPS prepares teams to recognize how system flow behaves under real production conditions, where minor variances in speed, spacing, or product handling can be early indicators of potential disruption.

Training focuses on understanding system behavior, executing accurate adjustments, and applying preventive maintenance practices that keep the line stable. Operators learn to identify early warning signs, maintain consistent flow, and make corrections without interrupting production. Maintenance teams gain clear inspection routines that strengthen runnability and support proactive uptime protection.

Manufacturers who implement EQUIPS see measurable gains in faster ramp-up, fewer micro-stops, and stronger ownership at the line. Competency at this level delivers more predictable operation and greater system stability.

When operators understand the system, they protect its performance.

Scaling Knowledge Across Multi-Plant Operations

Large manufacturers often struggle to maintain consistency across multiple facilities. Differences in shift practices, equipment interpretations, local habits, or informal “tribal knowledge” can lead to unpredictable performance from plant to plant. EQUIPS eliminates that variability by giving organizations a unified framework for operator competency and system-level execution.

Each program reflects the exact configuration of the line and subsystems in a specific plant while maintaining a consistent training standard across the entire enterprise. Materials are aligned to the customer’s internal terminology and branded to reinforce continuity. Operators who relocate between sites adapt quickly because the training model and performance expectations remain the same.

Supervisors can evaluate teams against shared benchmarks. Operators apply the same principles regardless of geography. A unified training framework delivers predictable performance and stable uptime across all facilities.

Training Embedded in the Full Project Lifecycle

EQUIPS is built into the Full Project Lifecycle. Training materials are developed early in the project so operators receive instruction based on how the system is engineered to run. By the time installation and commissioning begin, teams are positioned to learn the system with clarity and confidence.

Aligning training development with design, engineering, and startup accelerates the path from approval to stable production. EQUIPS then reinforces performance after startup through follow-up assessments and ongoing support, mirroring the disciplined approach IPM applies to every stage of the project.

Build Competency Now.

Protect Performance All Year.

Operator competency is a powerful lever of packaging line performance. If your line is preparing for new automation, system upgrades, or higher throughput targets, now is the time to align your team with the way the system is engineered to run.

Before performance gaps show up on the floor, talk with IPM about packaging equipment training that builds the operator capability needed to protect uptime from day one.