At Integrated Packaging Machinery (IPM), we know that dairy processors face one of the most demanding and fast-paced manufacturing environments in the food industry. From milk to cheese to yogurt, dairy products must be handled with precision, kept at safe temperatures, and moved quickly to meet regulatory standards and market expectations. That’s why we specialize in designing and integrating dairy packaging equipment into reliable automation systems that are tailored to the unique needs of dairy production lines.

Why Reliable Systems Matter in Dairy Processing

Efficiency, hygiene, and adaptability are more than just goals—they’re requirements. IPM’s conveyor and end-of-line systems are built to support these objectives, helping dairy processors minimize downtime, streamline operations, and maintain compliance with the strictest sanitation standards.

With dairy products ranging from cartons of milk to shrink-wrapped cheese blocks, packaging lines must handle a wide array of container types and sizes. Each SKU presents different demands, and IPM’s integrated approach ensures that our technology keeps up with change—not just today, but into the future.

IPM’s Conveyor Systems: Built for Complexity and Speed

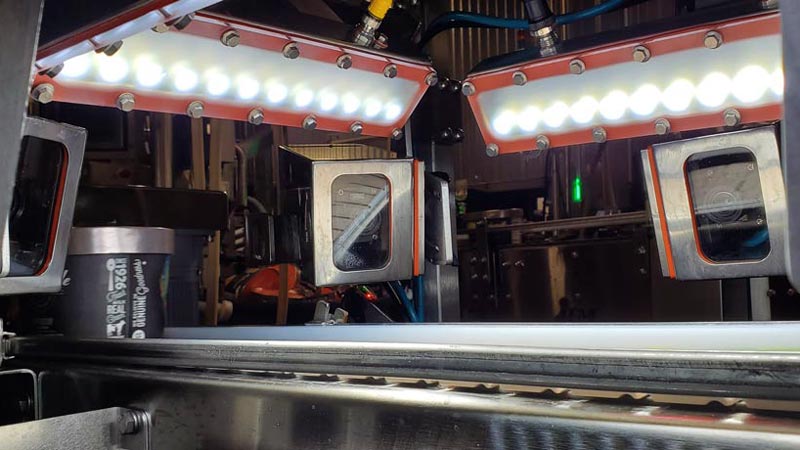

Our systems are designed for real-world dairy challenges. From multiple fillers to complex merging requirements, our conveyors manage the chaos so your operation can run smoothly. We develop smart accumulation systems and seamless merges that allow multiple lines to feed into a single palletizing system without disruption.

Dairy processors often need to switch between products and adapt their dairy packaging machines quickly. Whether you’re moving gallon jugs, single-serve bottles, or bags of shredded cheese, our conveyors adapt. We design for SKU flexibility and efficiency, so your operations don’t slow down when demand shifts.

And when it comes to speed, we don’t cut corners. Our servo-driven conveyors and synchronized motion controls are engineered to keep pace with today’s fastest filling technologies—without sacrificing gentle product handling.

Sanitation by Design

Every IPM system is built with food safety in mind. We work with each customer to ensure our designs align with their sanitation requirements. Whether you need full 3A-compliant dairy packaging equipment or a mixed environment with varying levels of hygienic compliance, our team integrates the right materials and layouts for your plant.

Our stainless-steel systems are engineered to withstand harsh washdown conditions. Modular construction and tool-free disassembly options make cleaning quick and easy, reducing downtime between production runs.

Palletizing That’s Flexible and Smart

In today’s dairy market, new products and packaging formats emerge frequently. That’s why IPM designs and integrates palletizing systems that are flexible and future-proof. From robotic palletizers to traditional layer-forming dairy packaging machines, we offer solutions that adapt to various case sizes, stack patterns, and product types.

With intelligent control systems and intuitive interfaces, operators can make adjustments to dairy packaging machines on the fly, monitor performance, and reduce manual intervention. Whether you’re palletizing shrink-wrapped bottles or cases of yogurt, our systems keep stacks stable and lines moving.

“Reliable systems are essential to optimizing your dairy processing workflow. With IPM’s integrated approach to conveyors and palletizing, you get more than just automation—you get peace of mind, efficiency, and a strategic edge.”

Cost-Efficient Solutions Through Strategic Engineering

We understand that not every part of your line needs the highest sanitary spec. That’s why our engineers strategically allocate materials and components based on your specific needs—maximizing food safety where it matters most and optimizing cost efficiency elsewhere.

For example, an IPM-designed line might start with stainless steel conveyors in primary packaging zones and transition to powder-coated steel in case packing or secondary packaging areas. This smart use of materials protects your products and your budget.

Our systems are also designed with ease-of-use in mind. Guideless conveyance, smart product transfers, and seamless line transitions allow your team to operate more efficiently and reduce unnecessary handling.

Automation That Empowers Your Workforce

At IPM, we believe automation should support—not replace—your workforce. With labor shortages affecting nearly every industry, including dairy, automation offers relief by handling repetitive, strenuous tasks and freeing up your team for higher-value work.

Our cobot and palletizing solutions operate around the clock with consistent precision. But they also integrate with your team’s workflow, offering intuitive controls and diagnostics to simplify operation and training.

Driving ROI Through Reliability and Uptime

The true value of automation within dairy packaging equipment lies in its reliability. Our systems are built to last, with predictive maintenance features and modular components that reduce unplanned downtime. With IPM, you don’t just get a machine—you get a system designed for long-term performance and support.

Real-time data collection and integration with plant-wide systems allow your team to track KPIs like OEE, yield, and throughput. This insight enables smarter decisions and continuous improvement across your entire operation.

The IPM Difference

Dairy processors trust IPM because we don’t just sell equipment—we engineer solutions. Every conveyor, every robotic arm, every palletizer within the dairy packaging machines we integrate is selected and designed with your unique production needs in mind. We collaborate with your team to ensure seamless integration, minimal disruption, and maximum ROI.

As dairy trends evolve—whether it’s new packaging formats, sustainability initiatives, or greater traceability—we evolve with them. From concept to commissioning, we’re your partner in building a smarter, more efficient dairy processing operation.

Reliable Systems from IPM

Reliable systems are essential to optimizing your dairy processing workflow. With IPM’s integrated approach to conveyors and palletizing, you get more than just automation—you get peace of mind, efficiency, and a strategic edge.

If you\’re looking to improve throughput, reduce labor strain, enhance sanitation, or increase system uptime, we’re ready to help. Let’s build a dairy line that’s as dependable as your brand.

Contact us here or call the IPM team at (616) 531-7758.