Most integrators are tied to one OEM. That model limits flexibility, constrains performance, and locks operations into technologies that may not be the best fit.

IPM takes a different approach. As an OEM-neutral packaging integrator, we evaluate technologies across the industry and engineer them to perform together as one, unified system. The result is packaging automation built for uptime, scalability, and measurable results.

Across modern packaging operations, speed to market, SKU variety, sustainability, and material innovation are constant. Relying on a single supplier often limits flexibility and slows response to change. OEM-neutral integration provides manufacturers with the agility to evolve their product lines as products, materials, and technologies advance.

How OEM-Neutral Integration Drives Performance

Packaging integration is complex. Multiple machine centers, evolving regulations, frequent changeovers, and tight production schedules create challenges that can slow performance.

When a system is designed around a single supplier, those challenges grow. Equipment that fits one function may create limits elsewhere in the line.

An OEM-neutral design approach eliminates those limits, giving manufacturers the freedom to select technologies based on proven performance, not brand preference. At IPM, this principle is built into every project. We focus on outcomes that protect uptime, extend equipment life, and strengthen return on investment.

Design Freedom That Fits the Operation

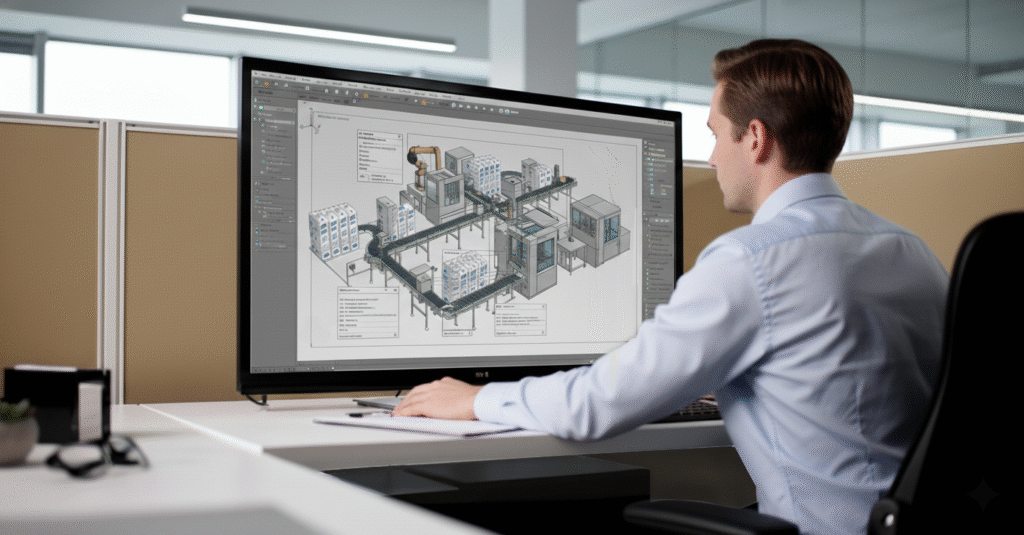

Every plant has unique requirements. Space constraints, throughput goals, and sanitation standards all shape what a packaging line must deliver.

IPM’s OEM-neutral design philosophy ensures every system is precisely matched to those conditions. Each machine center is chosen for performance, reliability, and serviceability. The integration is strategically automated and carefully balanced to maintain throughput, prevent bottlenecks, and ensure predictable operation.

By combining equipment from multiple OEMs, we design packaging systems that perform as one coordinated unit. This flexibility ensures every installation fits the plant, the product, and the long-term growth plan.

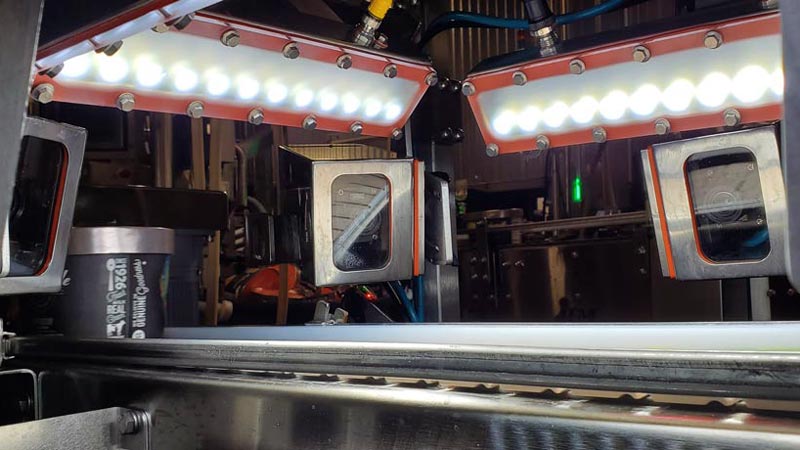

Performance That Protects Uptime

A packaging line is only as reliable as its least efficient machine center. IPM engineers each system as a unified whole, using system-as-a-machine principles to keep product moving smoothly from start to finish.

This synchronization is achieved through balanced accumulation, precise control logic, and line-speed modeling that keep every machine center operating in harmony. By preventing overfeeding or starving of critical machines, IPM preserves product integrity and throughput even under variable production loads.

Each system’s performance is validated through Factory Acceptance Testing and Site Acceptance Testing, confirming throughput targets before and after installation. These checks give manufacturers confidence that uptime and efficiency are achieved from the first production run.

By specifying and engineering every component to accommodate the system’s critical constraint, we stabilize throughput and prevent the small inefficiencies that cause downtime. The result is steady performance that protects production targets shift after shift.

Execution That Accelerates ROI and Reduces Risk

When technology selection is objective, design decisions become more efficient. An OEM-neutral integration model accelerates timelines because equipment is chosen for availability, compatibility, and proven results.

Every project follows IPM’s structured execution model, including Scope Freeze milestones that prevent scope drift and Factory Acceptance Testing that validates performance before installation. These checkpoints safeguard investment and eliminate surprises during commissioning.

With in-house mechanical, electrical, and controls engineering, IPM manages every stage of execution under one accountable partner. This structure shortens project schedules and helps customers realize performance and ROI sooner.

Engineering That Scales Across Multiple Facilities

For organizations that operate multiple plants, standardization and flexibility are both essential.

An OEM-neutral integration model enables IPM to apply project-specific design standards across sites while adapting to each facility’s layout, utilities, and regulatory environment.

IPM standardizes documentation, controls logic, and training resources across facilities, enabling multi-plant organizations to replicate proven performance. By maintaining common architecture while customizing for local utilities or regulations, we help enterprise operations expand capacity efficiently and maintain consistency plant to plant.

This enterprise-scale project intelligence reduces variability across sites and promotes uniform system behavior across a manufacturer’s entire production network.

Each system is engineered to run predictably and scale with future production demands, free from reliance on any single vendor or proprietary platform.

Collaboration That Strengthens the Industry

OEM-neutral integration is not a rejection of suppliers. It is a commitment to the best possible outcome.

IPM works closely with OEM partners, drawing on their expertise while coordinating the system as a whole. This cooperative model streamlines commissioning and ensures ongoing support is coordinated across vendors.

Customers gain a single point of accountability while benefiting from the collective expertise of multiple technology partners. The result delivers stronger performance for customers and supports long-term alignment among manufacturers, integrators, and equipment providers.

Training That Sustains Performance

Every integrated system performs only as well as the people who run it.

IPM’s EQUIPS training program unites materials from each OEM into one comprehensive curriculum. Operators learn how every component interacts and how to maintain the system for continuous uptime.

The program builds lasting competency, reduces reliance on external services, and maintains steady performance long after installation. Learn more about EQUIPS Training and how it sustains operator readiness across every IPM-integrated system.

The Outcome of OEM-Neutral Integration

A design approach built on OEM-neutral principles gives consumer packaged goods (CPG) manufacturers the freedom, flexibility, and confidence that come from systems integrated for performance, not preference. This approach eliminates bias, ensures the right technology is used in every application, and aligns the system around measurable performance.

Customers experience faster line readiness, higher overall equipment effectiveness, and long-term stability that continues well beyond startup. The result is packaging operations that adapt as markets, products, and materials evolve.

At IPM, this independence is a core part of how we engineer uptime. It is how we protect investments, accelerate ROI, and deliver packaging systems built to perform for the long term.

Start Maximizing Uptime

Learn how OEM-neutral integration can improve your line performance.