As environmental concerns continue to rise and consumer expectations shift, sustainability is no longer a “nice-to-have” in food and dairy packaging—it’s a must. From reduced carbon footprints to recyclability and energy-efficient production, the way food products are packaged has become a focal point for innovation across the entire supply chain. The market is demanding eco friendly food packaging solutions.

At Integrated Packaging Machinery (IPM), we see this shift not as a challenge, but as an opportunity—to engineer systems that not only perform with precision, but also align with our clients’ sustainability goals. Whether it’s dairy processors seeking to reduce waste, food manufacturers looking to extend shelf life with fewer preservatives, or packaging partners aiming to comply with tightening environmental regulations, sustainability is shaping the future of packaging—and we’re here to help build it.

The Growing Demand for Sustainable Packaging

Today’s consumers are increasingly aware of the environmental impact of what they eat, how it’s made, and how it’s packaged. According to a recent study by McKinsey, over 60% of U.S. consumers are willing to pay more for innovative sustainable food packaging. This trend is especially strong in the food and beverage sector, where packaging serves both a functional and symbolic role—preserving freshness while reflecting the values of the brand.

Meanwhile, government regulations and corporate sustainability targets are accelerating the move toward more eco-conscious practices. Global brands have committed to reducing plastic waste, increasing recyclability, and improving carbon efficiency across their operations. In the dairy sector, this includes finding alternatives to traditional rigid plastic jugs, reducing single-use materials, and optimizing every step of the packaging line to cut energy consumption and reduce product loss.

Where Packaging and Sustainability Meet

At its core, sustainable packaging is about reducing environmental impact without compromising performance. For IPM and our partners, that means:

- Optimizing packaging line efficiency to reduce energy use and product waste

- Automating packaging processes to ensure consistency and reduce labor demands

- Designing smarter systems that handle lightweight or alternative materials without compromising package performance or operating throughput and runnability.

Let’s explore how each of these plays out in the real world of food and dairy packaging.

Efficiency That Supports Sustainability

Sustainability often starts with eliminating inefficiency. On a packaging line, that means reducing downtime, maximizing throughput, and minimizing scrap and rework.

Our integrated systems are designed to maximize uptime and precision—two critical factors in reducing energy waste and unnecessary materials consumption. For example, in dairy facilities where perishable products must be handled at speed, even small inefficiencies can result in spoiled product or compromised food safety. The high-speed case-packing, palletizing and smart conveyors we specify and install help ensure availability, maintain consistency and minimize waste.

By integrating sensors and control systems that monitor line performance in real time, IPM helps operators quickly address bottlenecks or imbalances that could otherwise lead to overpackaging, product loss, or excess energy usage.

Packaging Materials: Less is More

The industry is seeing a shift with the eco friendly food packaging movement toward lighter, more sustainable materials—everything from recycled PET and HDPE to fiber- based containers and plant-based films. These changes can dramatically reduce the carbon footprint of a product, but they also bring new challenges for packaging equipment.

Lighter materials are more prone to deformation, which makes precise handling essential. Our automation systems are engineered to adapt to these newer substrates with flexible grippers, gentle handling features, and adjustable case sizes—all without sacrificing speed or reliability.

In one recent dairy integration, we helped a client switch from traditional gable-top cartons to a recyclable polyethylene option with a lighter footprint. Our custom end-of-line equipment adapted seamlessly, allowing the client to make the switch without compromising throughput.]

“Whether it’s implementing more efficient automation, adapting to the latest in recyclable packaging, or designing custom systems that reduce waste across the board, we’re ready to help manufacturers meet the demands of today and the expectations of tomorrow.”

Smart Automation Reduces Waste

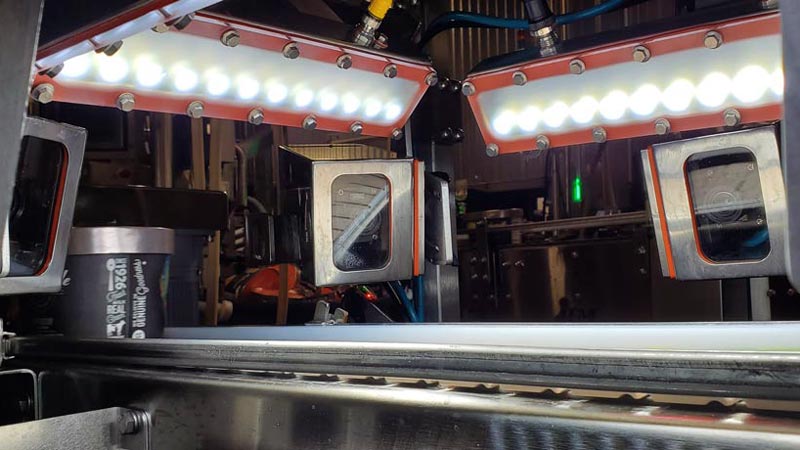

Every misaligned product or misprinted label means waste—of materials, energy, and labor. Automation significantly reduces the margin for error in packaging lines. At IPM, we employ vision-guided systems and robotic technologies that ensure precise placement, orientation, and inspection of every package.

In dairy applications, where shelf life is short and food safety is paramount, even small efficiencies matter. Cobots are one solution that collaborate ergonomically with human operators to handle repetitive tasks like palletizing—while ensuring accuracy and reducing injury risk.

Additionally, line control and related automation improves consistency, which plays a major role in streamlining a sustainable packaging solution. If your equipment can reliably seal a thinner film or apply an accurate label the first time, there’s no need for additional materials or rework. That’s innovative sustainable food packaging in action.

Modular Design = Long-Term Flexibility

Another way IPM supports sustainability is through specifying, installing and commissioning modular, scalable equipment. We design systems capable of growing with your business, reducing the need for complete overhauls when packaging formats change or production increases. This reduces equipment turnover, extends asset life, and helps reduce the environmental impact of manufacturing and transportation.

This flexibility is particularly important in the dairy, prepared foods and snacks sectors, where product lines often include a wide range of SKUs and packaging styles. Our modular systems can accommodate multiple formats with simple changeovers—reducing downtime, operator training, and waste during transitions.

Reducing Secondary Packaging Impact

Primary packaging often gets the spotlight, but secondary packaging—trays, boxes, shrink wrapped bundles —plays a huge role in overall environmental impact. We work with food and dairy clients to streamline their secondary packaging operations, integrating systems that use right-sized cartons, eliminate unnecessary filler, and reduce stretch film usage through more efficient palletizing techniques.

The automated case erectors, packers, and sealers IPM specifies help, in sequence, to eliminate inconsistencies and oversizing that contribute to excess cardboard use. And our end-of-line integration services include options for reusable totes, corner board reduction, and palletizing systems that minimize stretch film waste.

Food Safety + Sustainability Go Hand in Hand

For dairy processors, packaging sustainability can’t come at the expense of food safety. That’s why we design our systems to support sanitary design principles, prevent cross-contamination, and preserve product integrity—all while reducing waste and energy usage.

A sustainable package that fails to protect its contents is counterproductive. Our approach ensures that every package not only meets environmental standards but also supports product freshness, regulatory compliance, and brand trust.

Data-Driven Sustainability Gains

Data is key to unlocking sustainable improvements. With integrated tracking and analytics, our systems help manufacturers measure critical KPIs—energy use, material throughput, downtime events, and more. This visibility enables continuous improvement and smarter decision-making that drives sustainability forward.

Imagine a dairy plant identifying where film waste is highest, or when excessive energy is used during startup cycles. That’s actionable insight that leads to real-world results—and it’s built into IPM’s integrated packaging systems.

The Path Ahead: Collaborating for a Greener Future

Sustainability is not a destination—it’s a continual evolution. And at IPM, we’re committed to walking that path alongside our partners in the food and dairy industry. Whether it’s implementing more efficient automation, adapting to the latest in recyclable packaging, or designing custom systems that reduce waste across the board, we’re ready to help manufacturers meet the eco-friendly food packaging demands of today and the expectations of tomorrow.

Let’s build a smarter, cleaner, and more sustainable packaging operation—together.

Interested in upgrading your food or dairy packaging systems with sustainability in mind?

Contact us here or call the IPM team at (616) 531-7758.