In today’s rapidly evolving food and dairy landscape, packaging is no longer just a container—it’s a critical component of product integrity, brand trust, and supply chain efficiency. Smart packaging, a once-futuristic concept, is now taking center stage as food and beverage producers seek ways to improve traceability, reduce waste, and meet growing consumer expectations for transparency and freshness.

At IPM, we believe smart packaging isn’t just about innovation for the sake of it—it’s about integrating intelligent, real-time solutions that enhance safety, efficiency, and uptime across the entire packaging line. Whether you’re moving milk, cheese, yogurt, or ice cream, smart packaging has the potential to change how the food and dairy industry delivers quality from plant to plate.

What Is Smart Packaging?

Smart packaging refers to packaging systems embedded with technology that provides additional functionality beyond containment and protection. Broadly speaking, there are two primary types:

- Active Packaging: Designed to interact with the contents, often to extend shelf life or maintain product quality. Examples include oxygen scavengers, moisture absorbers, and antimicrobial films

- Intelligent Packaging: Provides data or communicates information—such as time-temperature indicators, freshness sensors, QR codes, or RFID tags—that helps track product condition or location in the supply chain.

When paired with automated packaging systems like the ones we engineer at IPM, smart packaging becomes more than just a feature—it becomes a performance-enhancing tool for food producers.

The Driving Forces Behind Smart Packaging in Food and Dairy

1. Shelf Life and Freshness

Dairy products are highly perishable and sensitive to temperature fluctuations. Smart food packaging can include time-temperature indicators that change color if a product has been exposed to unsafe conditions. These small, low-cost devices help brands and retailers ensure product integrity and reduce the likelihood of spoilage reaching the shelf—or worse, the consumer’s fridge.

For producers, this data can also drive improvements in cold chain management and equipment maintenance. At IPM, we help our clients ensure that their packaging line supports these intelligent features without adding unnecessary steps or downtime.

2. Food Safety and Traceability

In an era where a single contamination issue can cause widespread recalls and erode customer trust, traceability is no longer optional. Smart food packaging equipped with QR codes, RFID chips, or blockchain-based data allows producers, retailers, and even consumers to access critical information—batch number, production date, ingredient source, and more.

When integrated into a modern packaging line, this level of traceability can be automated, scalable, and compliant with evolving food safety regulations. As a leading smart packaging company, IPM specializes in building automation systems that support such seamless integration, enabling faster, safer, and more transparent operations.

3. Consumer Engagement and Transparency

Modern consumers, especially in younger demographics, want to know more than just what’s in their food—they want to know where it came from, how it was made, and whether it was handled responsibly. Intelligent packaging opens the door to interactive experiences using smartphones, augmented reality, or personalized content.

Imagine scanning a yogurt container and instantly accessing a video tour of the dairy farm, nutritional data, or a coupon for your next purchase. It’s not just about selling a product—it’s about building a relationship. IPM’s automation systems are built to handle these digitally enhanced packaging solutions while maintaining speed and reliability at scale.

Smart Packaging Technologies Gaining Ground

Let’s take a closer look at some of the most impactful smart packaging innovations entering food and dairy production lines today:

• RFID and NFC Tags

Used for real-time tracking and inventory management, RFID (Radio Frequency Identification) and NFC (Near Field Communication) tags are helping brands monitor products across their entire supply chain. These tags can be embedded in the packaging or attached during secondary packaging.

For dairy producers managing temperature-sensitive products with tight expiration windows, RFID allows for better warehouse rotation, targeted recalls, and dynamic inventory updates—all while reducing labor.

• Digital Watermarks

Digital watermarks—imperceptible codes printed across packaging surfaces—are being used to improve sortation and recycling, enhance traceability, and provide anti-counterfeit measures. As sustainability becomes a priority in food packaging, smart watermarks ensure materials are correctly identified and sorted, supporting closed-loop recycling systems.

• Freshness Sensors

Gas sensors, pH indicators, and biosensors can detect the presence of spoilage gases like ammonia or carbon dioxide, offering real-time insights into freshness. In dairy products where spoilage can occur quickly, these technologies can significantly reduce food waste and ensure safety from production to end-user.

“Smart packaging is not a trend—it’s a transformation. In the food and dairy sector, where product integrity, safety, and transparency are paramount, smart packaging technologies are redefining how producers connect with consumers, manage operations, and protect their brand.”

Automation + Intelligence: The IPM Advantage

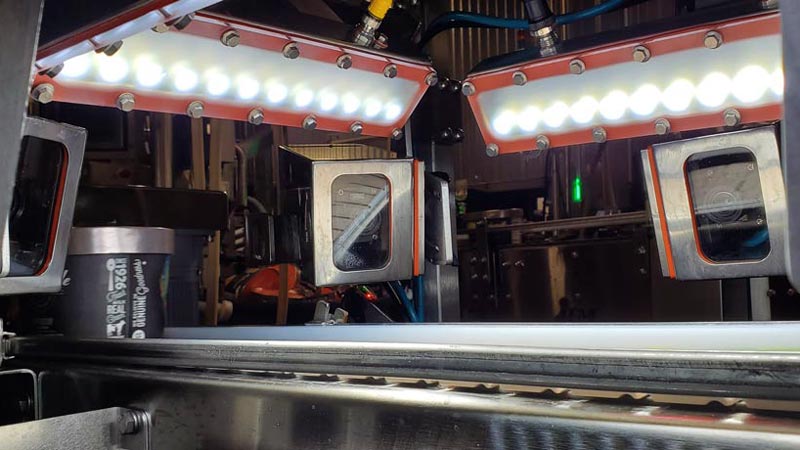

Smart packaging doesn’t work in a vacuum—it must be supported by packaging systems that are equally intelligent. As a smart packaging company, that’s where IPM’s integrated automation expertise comes in.

Our role is to ensure your packaging lines are ready for the demands of smart packaging—from precise label application and digital coding to sensor integration and data syncing. Whether you\’re retrofitting an existing line or designing a new system from the ground up, we bring deep experience in:

- Collaborative robotics (cobots) for flexible, operator-friendly automation

- Vision systems for inspection and real-time data collection

- OEM-neutral integration for compatibility with a range of smart packaging tools

- Custom HMI and controls programming that allows seamless data capture and reporting

When smart packaging is coupled with smart automation, the result is greater uptime, cleaner data, and a supply chain that learns and improves with every cycle.

Real-World Applications in Dairy Packaging

Here’s how smart packaging and IPM’s integration expertise intersect in the real world:

- Yogurt packaging lines that incorporate freshness indicators and use collaborative robots to pack mixed SKU cases for retail.

- Milk bottling plants that leverage RFID to manage expiration-date sorting and automatically flag inventory nearing the end of shelf life.

- Cheese producers using QR codes to tell the story behind their products—and sensors to ensure those cheeses remain safe in transit.

Each of these applications relies on a tightly integrated smart food packaging system that’s designed to accommodate next-gen packaging without disrupting line speed or product quality. That’s what IPM delivers.

Looking Ahead: What’s Next for Smart Packaging?

As food and dairy producers embrace digitization, smart packaging will continue to evolve. Expect to see:

- AI-enhanced predictive analytics based on sensor data

- Expanded blockchain adoption for end-to-end traceability

- Biodegradable smart materials that combine sustainability with functionality

IPM is already helping clients plan for what’s next—future-proofing their lines for the inevitable increase in smart packaging demands.

Final Thoughts

Smart packaging is not a trend—it’s a transformation. In the food and dairy sector, where product integrity, safety, and transparency are paramount, smart packaging technologies are redefining how producers connect with consumers, manage operations, and protect their brand.

At IPM, we integrate more than machines—we integrate possibility. If you’re ready to make your packaging line smarter, faster, and more future-ready, let’s talk.

Contact us here or call the IPM team at (616) 531-7758.