Connect with IPM

EQUIPS is IPM’s fully customized, comprehensive training and maintenance program. Every training is tailored for the customer, aligned with their plant’s processes, and designed around the exact equipment operators will use, ensuring learning is practical, plant-specific, and directly applied on the floor.

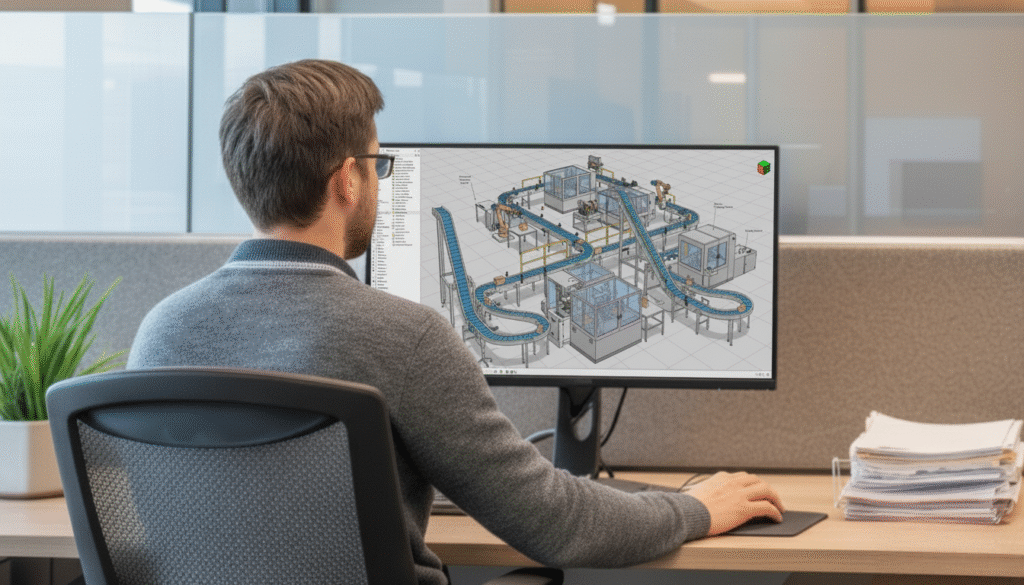

The goal of EQUIPS is clear: to build operator competency, enhance problem solving, and sustain uptime by providing teams with the knowledge and tools they need to run integrated packaging systems as a seamless machine center.

Training Formats Tailored to Your Team

EQUIPS combines multiple learning formats into a customized program. As an OEM-neutral integrator, IPM develops training that spans all OEMs in your system, uniting them into a comprehensive package. Our team compiles manuals and materials from every OEM in your line and integrates them into branded training resources. Operators and maintenance staff learn not only how to run individual machines, but also how the entire packaging line operates as a unified system.

Training is delivered on-site in a classroom setting, hands-on at the machinery or line, and through self-paced online modules. Each format is adapted to your operation, so employees gain knowledge that is relevant and immediately applicable.

Comprehensive Training Components:

Facilitation

Led by an EQUIPS project manager in coordination with OEM vendors and customer personnel. Classroom sessions are guided by subject matter experts and supported with branded handbooks, presentations, and essential documentation such as lockout/tagout and start-up/shut-down procedures. Each program concludes with a skill assessment to confirm operator readiness.

Basic Training

Hands-on instruction at the machinery or line, led by a subject matter expert. Training is reinforced with concise handouts that cover essential machine functions and daily operation practices.

E-Courses

Self-paced online modules that strengthen confidence and standardization across teams. Interactive modules, videos, and photos reinforce concepts, support packaging equipment predictive maintenance, and sustain learning well beyond installation.

Every EQUIPS program follows a proven structure to ensure completeness. From this framework, all materials are tailored to your plant and equipment.

By combining assessments, certification, and repeatable resources, EQUIPS ensures training is retained, applied, and scaled across the organization. The result is stronger operator competency, faster ramp-up, improved OEE, and sustained uptime with less reliance on OEM service.

Connect with IPM

What makes EQUIPS different from other OEM training programs?

EQUIPS is developed by IPM, an OEM-neutral integrator. That means training isn’t limited to a single brand of equipment. Instead, IPM compiles manuals and materials from every OEM in your line and integrates them into one comprehensive program. The result is cohesive training that demonstrates to operators how individual machines function and how the entire packaging line operates as a unified system.

How does EQUIPS support packaging equipment predictive maintenance?

EQUIPS includes e-learning modules and hands-on instruction that reinforce predictive maintenance practices. By standardizing daily operations, troubleshooting, and maintenance routines, EQUIPS helps teams identify issues early, reduce unplanned downtime, and extend equipment life. This proactive approach directly supports predictive maintenance goals.

How is EQUIPS training delivered?

EQUIPS combines multiple formats to give teams the knowledge and confidence to run packaging lines effectively. Training is delivered on-site in classroom sessions led by subject matter experts, hands-on at the machinery or line with guided practice, and through self-paced e-learning modules that extend learning long after installation. This blended approach ensures training is practical, relevant, and reinforced over time.

How does EQUIPS improve OEE monitoring and uptime?

EQUIPS training teaches operators to view the entire packaging line as a system rather than a collection of machines. By building competency in daily operations, troubleshooting, and problem-solving, teams reduce their reliance on OEM service calls and respond more quickly to issues. The result is higher operator confidence, stronger OEE performance, and sustained uptime. Learn more about IPM’s Uptime Audit.

Is EQUIPS designed only for operators, or also for maintenance and engineering teams?

EQUIPS is demand-based training tailored to the workforce at each plant. Programs are developed for operators, maintenance teams, engineers, and supervisors, with content customized to the needs of each group. This ensures every role has the knowledge and tools required to support safe, efficient, and reliable packaging line performance.