Uptime is the only time that matters!

SURE-thing Pallet Conveyor Solutions

Leaders in conveyor systems and design.

Businesses that load, ship, or store large products or large quantities often incorporate pallets into their operations. However, it is not always an easy task handling these pallets and the products that are loaded onto them in a timely and cost-effective way. Integrated Packaging Machinery is the industry leader of quality pallet conveyor systems designed to help improve the efficiency and effectiveness of pallet utilization.

Benefits of Pallet Conveyors

Depending on how the pallet is loaded, utilized, stored, or shipped could determine how the pallet conveyor is implemented into the operations. Some conveyors are widely used and are more of a heavy-duty, robust style of conveyor, while others are designed to fit within a line of conveyors.

These system solutions are most commonly used within the because of the large loads often associated with production. Some of the more common benefits of pallet handling conveyors include:

- They move incoming pallets to the right place at the right time for loading, unloading, or for the storage of bulk goods.

- They transport empty and full pallets into position for palletizing or depalletizing.

- They ensure efficient, stable pallet flow into and out of storage and allow for proper sequence for outbound shipments.

- Direct stable and efficient pallet flow to and from dense automated storage.

- Ensure consistent, smooth flow for end-of-line stacking, labeling or stretch-wrapping operations.

UPTIME IS THE ONLY TIME THAT MATTERS!

Types of Pallet Conveyors

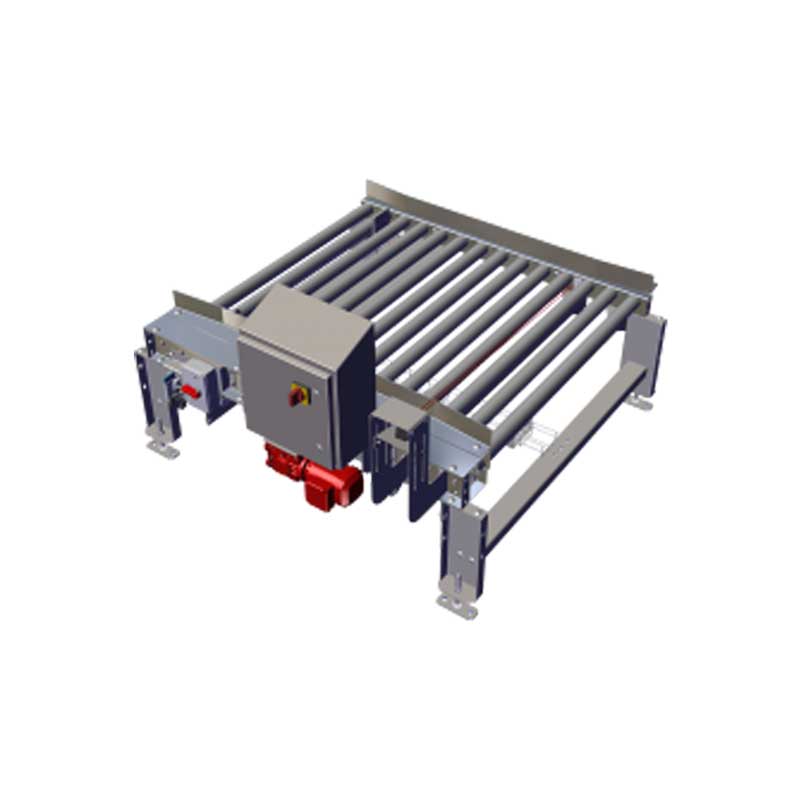

Chain Driven Live Roller (CDLR)

Widely used, heavy-duty, robust style of conveyor. It is typically used for transportation of heavy pallet loads.

Sprockets are attached to the roller tubes and short loops of roller chain transfer drive force from roller to roller. Available in stainless-steel and mild-steel. Contact IPM today to learn more about our pallet conveyor options.

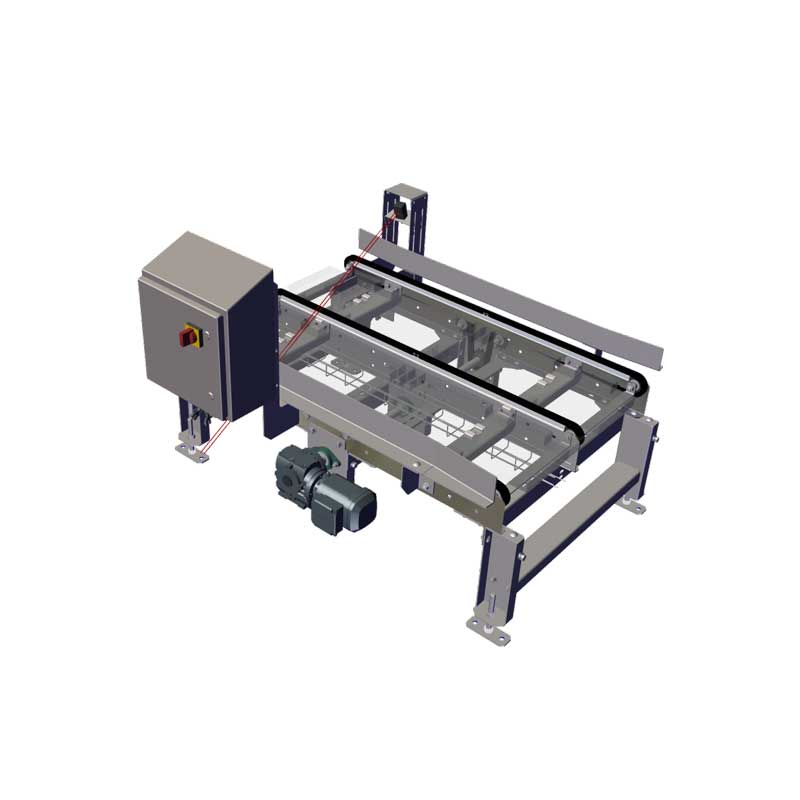

Multi-Strand Chain (MSC)

This conveyor is a heavy-duty transportation conveyor that utilizes straight running roller chain to support the pallet load. The chain serves as the carrying surface for the load.

The center positioned drive unit connects the strands of chains by means of a drive shaft and sprocket configuration and allows for reversible drive operation.

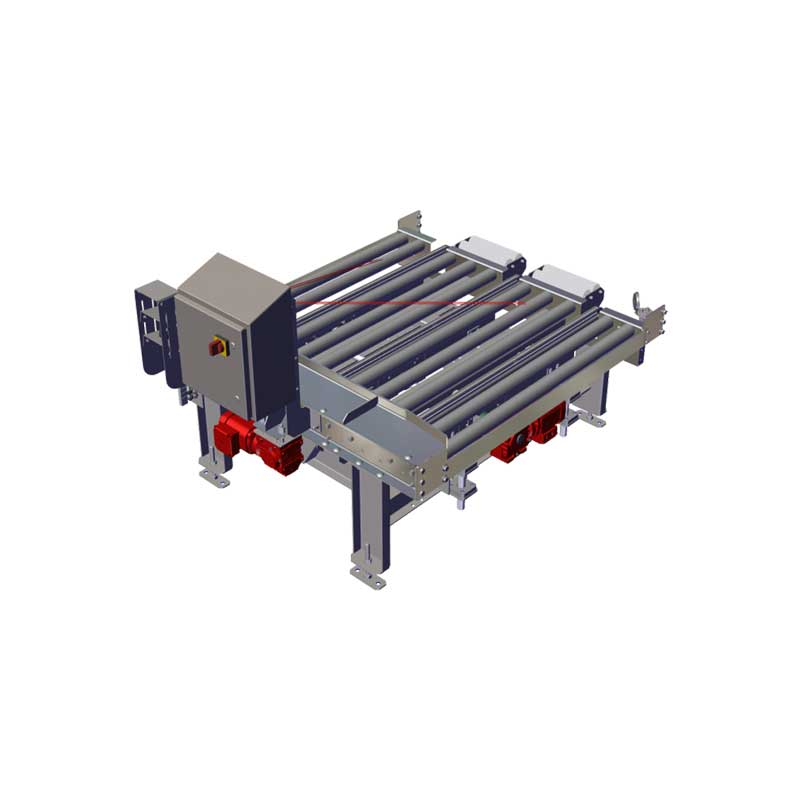

Right Angle Transfer Unit

Conveyor lanes raise up between the rollers and lift the load above the surface. In the raised position, the chain conveyor moves the unit load off at a right angle.

Lifting operation of the transfer is a linear motion that translates to vertical motion with the use of air or hydraulics. (Electrically actuated as an option).

Why Choose IPM?

These benefits noted above make pallet-based conveyors an ideal solution for high-precision assembly, machining, inspection, and other positioning tasks of heavy pallet loads. The engineering consultants at Integrated Packaging Machinery provide high-quality automated packaging systems and solutions for your facilities end-of-line packaging needs.